-

-

Phone +91 9825323199 | +91 9727166988

Separation of solid particles from gases by a textile filter media at a very high temperature is an essential part of an industrial process, Contribute to the recovery of precious material & improvement in pollution control.

In a Fabric dust collector, dust laden gas is drawn through air permeable fabric, normally in the form of a tubular bag of different diameter & length where the gas passes through the fabric & the particles are retained. In this process the gas is filtered & clean gas comes out of dust collector/bag filter.

To meet the government environmental regulation the filtration efficiency of the media is very important.

Our Woven Glass fiber filter media is designed with specific properties like yarn quality & count; Yarn Density; Weave pattern to achieve required parameter for optimum efficiency in filtration. at a temperature of 260º C on continuous rating.

Special chemical finishes are imparted to withstand severe chemical attack, Mechanical Stress & abrasion in extreme condition.

A proportionate mixture of Silicone; Graphite & PTFE which protects media against abrasion; While it provides limited protection against chemical attack, This finish is recommended for Cement & Foundry Industries.

A ten percent add on of PTFE on the filter media, protects it from abrasion because PTFE encapsulates the glass filament. Recommended for utility based load boilers

This is formulated of a mixture of Silicone; Graphite; PTFE & an Acid resistant polymer, This prevents Filter media against severe Acid & Chemical attacks while also reducing abrasion, Recommended for Industrial Boiler & Carbon Black

The main challenges faced by Fiberglass Filter media were short bag life due to acid attacks which corrodes the glass filament, Also as pollution norms became more & more stricter, ePTFE Membrane laminated Filter Media is the need of the hour.

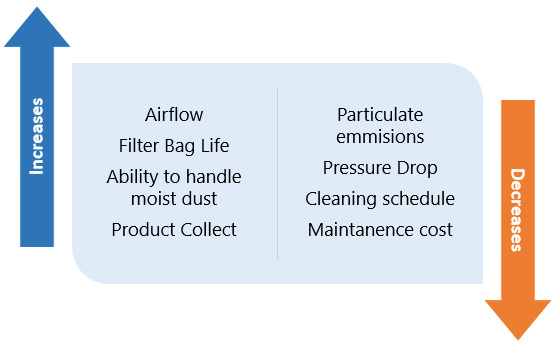

ePTFE membrane filter media can bring about a wide range of benefits for your fabric

Filter baghouse, the unique structure of our membrane prevents the penetration of fine dust particulates into the supporting substrate and facilitates excellent cleanability due to their non-stick

Characteristics.

ePTFE Membrane laminated filter media operates by utilizing surface filtration principles. The membrane on the filtering surface of the media prevents penetration of fine particles into the substrate. When cleaned, there is a near total removal of dust from its surface. It is this twin-action characteristic that enables ePTFE membrane laminated Filter Media to increase airflow without compromising baghouse DP. The permeability of media is maintained at all times and so DP is not only lower, but is kept constant throughout the life of the filter elements.

Below images display the effects of ePTFE Membrane laminated Fabric on the Baghouse.

| Products | GSM | Weave Pattern | Finish Code | Loss on Ignition % | Thickness in mm | Air Permeability L/dm2/min @200 Pa | Tensile Strength | Mullen Burst Strength Kpa | Temperature | Available Widths mm | ||

| Warp N/2.54 CM | Weft N/2.54 CM | Continuous deg C | Surge Deg C | |||||||||

| Fiberglass Filter Media for Reverse Air Baghouse Application | ||||||||||||

| ARF-350(1x3)RH | 350 | (1x3) RH Twill | AR | 8% | 0.34-0.37 | 250-400 | 930 + | 980 + | >2950 | 260 | 290 | 1040mm;2040mm |

| PTFE-350-(1X3) RH | 350 | (1x3) RH Twill | PTFE | 8% | 0.34-0.37 | 250-400 | 930 + | 980 + | >2950 | 280 | 310 | 1040mm;2040mm |

| SGT-450-(1x3)RH | 450 | (1x3) RH Twill | SGT | 8% | 0.40-0.45 | 250-400 | 1760 + | 1175 + | >3950 | 260 | 290 | 980mm |

| SGT-520-(1X3)RH | 520 | (1x3) RH Twill | SGT | 8% | 0.45-0.50 | 250-400 | 1760 + | 880 + | >2950 | 260 | 290 | 980mm |

| ePTFE Membrane Laminated Fiberglass Filter Media for Reverse Air Baghouse Application | ||||||||||||

| eARF-350-(1x3)RH | 350 | (1x3) RH Twill | ePTFE + ARF | >10% | 0.34-0.36 | 19-35 | 930 + | 980 + | >2950 | 260 | 290 | 2040mm |

| ePTFE-350-(1x3)RH | 350 | (1x3) RH Twill | ePTFE + PTFE | >10% | 0.34-0.36 | 19-35 | 930 + | 980 + | >2950 | 280 | 310 | 2040mm |

| Fiberglass Filter Media for Pulse Jet Baghouse Application | ||||||||||||

| SGT-600-DFT | 600 | Double Fill Twill | SGT | 8% | 0.50-0.60 | 250-400 | 1760 + | 1760 + | >5400 | 260 | 290 | 1040mm;1650mm |

| SGT-830-DFT | 830 | Double Fill Twill | SGT | 8% | 0.65-0.75 | 190-300 | 1760 + | 2250+ | >5400 | 260 | 290 | 1040mm;1650mm |

| ARF-830-DFT | 830 | Double Fill Twill | AR | 8% | 0.65-0.75 | 190-300 | 1760 + | 2250 + | >5400 | 260 | 290 | 1040mm;1650mm |

| PTFE-830-DFT | 830 | Double Fill Twill | PTFE | 8% | 0.65-0.75 | 190-300 | 1760 + | 2250 + | >5400 | 280 | 310 | 1040mm;1650mm |

| ePTFE Membrane Laminated Fiberglass Filter Media for Pulse Jet Baghouse Application | ||||||||||||

| ePTFE-750-DFT | 750 | Double Fill Twill | ePTFE + ARF | >10% | 0.65-0.75 | 19-35 | 1760 + | 2250 + | >5400 | 280 | 310 | 1040mm;1650mm |

| eARF-750-DFT | 750 | Double Fill Twill | ePTFE + PTFE | >10% | 0.65-0.75 | 19-35 | 1760 + | 2250 + | >5400 | 260 | 290 | 1040mm;1650mm |

Stiching thread is a most important member of the filter bag, It must withstand very high temperature, abrasion and should not giveaway during entire operation of Bag. We offer 100% Pure PTFE Stitching thread & PTFE Coated Fiberglass Stitching thread. 1250 Dernier & 1570 Dernier pure PTFE Thread are most commonly used and are ideal to withstand extreme conditions.