-

-

Phone +91 9825323199 | +91 9727166988

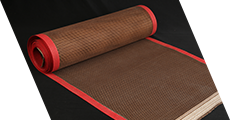

Polytetrafluoro ethylene (PTFE) is a fluoropolymer having unique properties, Fiberglass is strong light weight material. Combination of both material,when Glass Fiber is coated with PTFE produces combined excellent properties

Shrinath is also the name of leadership in manufacturing of high performance process belts. Our industrial conveyor belts combine the excellent properties of these two extraordinary material PTFE & Fiberglass.

We manufacture our belts from below mentioned fabrics

| Products | GSM | Thickness | Colour | Tensile Strength | ||

| Mils | Mm | Warp Kg/2.5CM |

Weft Kg/2.5CM |

|||

| 6507-P | 75 | 3 Mil | 0.07 | Brown | 30 | 20 |

| 6508-N | 130 | 3 Mil | 0.08 | Brown | 30 | 18 |

| 6012-B | 260 | 5 Mil | 0.12 | Black | 50 | 50 |

| 5615-N | 280 | 6 Mil | 0.15 | Brown | 45 | 45 |

| 6025-R | 530 | 10 Mil | 0.25 | Brown | 100 | 85 |

| 6025-B | 515 | 10 Mil | 0.25 | Black | 86 | 78 |

| 6035-R | 725 | 14 Mil | 0.35 | Brown | 110 | 85 |

| 6035-B | 680 | 14 Mil | 0.35 | Black | 100 | 80 |

| 6040-B | 780 | 16 Mil | 0.40 | Black | 115 | 90 |

| 6055-N | 1150 | 22 Mil | 0.55 | Brown | 140 | 130 |

| Leno 4 x 4 DWR | 580 | 40 Mil | 1.0 | Brown | 100 | 190 |

| Leno 4 x 4 SWR | 470 | 36 Mil | 0.90 | Brown | 100 | 96 |

| Leno 4 x 4 SWB | 470 | 36 Mil | 0.90 | Black | 85 | 80 |

| Leno 2 x 3 SWR | 500 | 30 Mil | 0.78 | Brown | 125 | 100 |

Belts end are cut straight or angularly at different angle overlapped to 25mm to100 mm and heat sealed. It gives a very strong joint strength of joint is more than the basic fabric strength. This joint makes the belt endless.

Both ends of the belts are cut straight or at different angles and butted together and the piece of PTFE / Glass Fabric of same or greater thickness is fused at the underside of the belt to get a smoother surface on top. Sometimes a piece of thin fabric is fused on the top side to protect the joint. This makes the belt endless.

Two layer of PTFE/ Glass Cloth are laminated with staggered joint to achieve uniform thickness of the belt all over the belt to make a strong and endless belt.

A Leno Woven Fabric with braided thin Kevlar rope in fill direction which forms the loop, is used as a splice. This is stitched on both ends of Leno woven mesh belt anda mono peek pin is used to complete the joint. This Splice offers maximum airflow & flexibility at jointed portion. This males the belt open ended.

This is a strong metallic splice where metallic alligator is fixed on both ends of the belt & connected by a metallic Pin to complete the joint. This makes the belt open ended. Open end belts are required where it is difficult to dismantle the machine & install the belt.

In this splice, small fingers are cut by a template at both ends of the belt and fixed in the alternative grooves and a piece of PTFE Coated Fiberglass Fabric is heat sealed on the top & bottom side of the joint to make it endless. It is an improvised butt joint which provides flexibility to run belt even at the smaller diameter of rollers of machine.

Small dimension of fabric, heat sealed on both edges of the belt is cut alternatively to make hinges like fixing. A non-metallic pin is inserted to complete the joint. This belt is used where use of metal is undesirable.

Both edges of the belt need protection from tearing while running and coming in contact with metallic components. Skived PTFE Film or PTFE coated Fiberglass cloth is fused on both edges or stitched by 100% PTFE Thread.

Our open mesh belts are used in screen printing to transport imprinted materials through drying ovens and cooling chambers. These belts are long lasting and perform well over a wide range of operating temperatures.

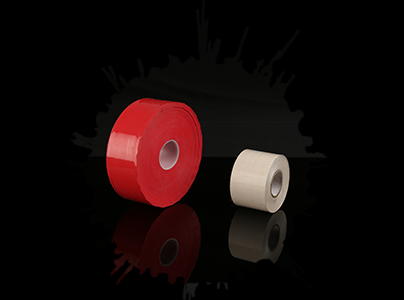

Seamless belts for band sealer is available in single layer fabric which is cut,woven & PTFE Coated from a seamless fabric, Larger Size of seamless is also available as per dimension

2PLY belts is a laminated belt with two layer of PTFE Fabric, Basically used in band sealer application for LDPE pouch packaging for powder packaging.

Silicone Rubber Belt for Shrink tunnel for packaging equipment for packing stationery & food products is available